In manual programming, the part programmer specifies the machining instructions on a form called a manuscript. Manuscripts come in various forms, depending on the machine tool and tape format to be used. For example, the manuscript form for a two-axis point-to-point drilling machine would be different than one for a three-axis contouring machine. Three representative manuscript forms are illustrated in Figure 9.3. As mentioned, the manuscript is a listing of the relative tool and workpiece locations. It also includes other data, such as preparatory commands, miscellaneous instructions, and speed/feed specifications, all of which are needed to operate the machine under tape control. The manuscript is designed so that the NC tape can be typed directly from it on a Flexowriter or similar tape-punch device.

As mentioned, the manuscript is a listing of the relative tool and workpiece locations. It also includes other data, such as preparatory commands, miscellaneous instructions, and speed/feed specifications, all of which are needed to operate the machine under tape control. The manuscript is designed so that the NC tape can be typed directly from it on a Flexowriter or similar tape-punch device.

We shall divide manual programming jobs into two categories : point-to-point jobs and contouring jobs. Except for complex work parts with many holes to be drilled, manual programming is ideally suited for point-to-point applications. On the other hand, except for the simplest milling and turning jobs, manual programming can become quite time-consuming for applications requiring continuous-path control of the tool. Accordingly, we shall only concern ourselves with manual part programming for point-to-point operations in this chapter. Manual contour programming requires such tedious and detailed calculations that the space needed for the topic would be more than is warranted by the basic purpose of this book, which is to survey the field of automated manufacturing systems. Contouring is much more appropriate for computer-assisted part programming (Sections 9.4 and 9.5).

The basic method of manual part programming for a point-to-point application is best demonstrated by means of an example.

EXAMPLE 9.2

Suppose that the part to be programmed is a drilling job. The engineering drawing for the part is presented in Figure 9.4. Three holes are to be drilled at a diameter of 31/64 in. The close hole size tolerance requires reaming to 0.500 in. diameter. Recommended speeds and feeds are given[1] as follows

dia Speed (ft/min) Feed (in./rev)

0.484-in.-diameter drill 75 0.006

0.500-in.-diameter reamer 50 0.010

The NC drill press uses the tab sequential tape format. Drill bits are manually changed by the machine operator, but speeds and feeds must be programmed on the tape. The machine has the floating-zero feature and absolute positioning.

[1] Recommended cutting speeds and feeds could be obtained from machinability data handbooks

The first step in preparing the part program is to define the axis coordinates in relation to the work part. We assume that the outline of the part has already been machined before the drilling operation. Therefore, the operator can use one of the comers of the part as the target point. Let us define the lower left-hand comer as the target point and the origin of our axis system. The coordinates are shown in Figure 9.5 for the example part. The x and y locations of each hole can be seen in the figure.

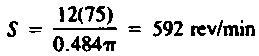

The machine settings for speed and feed must next be determined. For the drill, the spindle speed would be computed from Eq. (8.8) :

The machine settings for speed and feed must next be determined. For the drill, the spindle speed would be computed from Eq. (8.8) :

The feed rate is determined from Eq. (8.9) :

The feed rate is determined from Eq. (8.9) :

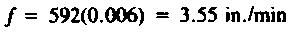

Similarly, for the teaming operation,

Similarly, for the teaming operation,

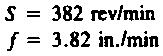

The completed manuscript would appear as in Figure 9.6. The first line shows the x and y coordinates at the zero point. The machine operator would insert the tape and read this first block into the system. (A block of instruction corresponds generally to one line on the manuscript form.) The tool would then be positioned over the target point on the rnachine table. The operator would then press the zero buttons to set the machine.

The completed manuscript would appear as in Figure 9.6. The first line shows the x and y coordinates at the zero point. The machine operator would insert the tape and read this first block into the system. (A block of instruction corresponds generally to one line on the manuscript form.) The tool would then be positioned over the target point on the rnachine table. The operator would then press the zero buttons to set the machine.

The next line on the manuscript is RWS, which stands for rewind-stop. This signal is coded into the tape as holes in columns 1, 2, and 4. The symbol stops the tape after it has been rewound. The last line on the tape contains the m30 word, causing the tape to be rewound at the end of the machining cycle.

The next line on the manuscript is RWS, which stands for rewind-stop. This signal is coded into the tape as holes in columns 1, 2, and 4. The symbol stops the tape after it has been rewound. The last line on the tape contains the m30 word, causing the tape to be rewound at the end of the machining cycle.

Other m-words used in the program are m06, which stops the machine for an operator tool change, and m13, which tums spindle and coolant on. Note in the last line that the tool has been removed from the work area to allow for changing the workpiece.

Ping balik: part III Numerical Control Production Systems | CuikSuiqbad RekaDayaUpaya